3D printing pancreas on models make it possible to try gallstone treatment devices with models of the body that are exactly like the real thing, which lets people make sure that the devices are correct and see how well they work. The pancreas on model technology from Trandomed has specific structural features like the pancreatic notch, head, body, and uncinate process, which makes testing settings for medical device makers more realistic. These advanced models deal with big problems in traditional testing methods. They also make the process of creation cheaper and improve health results.

When treating gallstones, medical device makers need to have a very clear picture of the complicated ways the pancreas, bile tubes, and nearby blood vessels are connected to each other. Creating realistic modeling settings can be hard with traditional testing methods. This can make development take longer and raise safety issues. The creation of advanced 3D-printed pancreas models has changed the way makers test their devices. These models are so accurate and useful that they can be used for both lab and field testing.

Challenges in Gallstone Treatment Device Testing

It is hard to test gallstone treatment devices because standard models of the pancreas have problems. It is harder for conventional plastic models to correctly mimic nearby organs and bodily functions because they often don't have detailed anatomy or realistic tissue qualities. This lack makes preliminary testing less useful, which means longer development times and higher costs, as well as safety risks when gadgets don't work the way they are supposed to in clinical settings.

Limitations of Traditional Pancreas Models

Traditional pancreatic models have a lot of problems that make it hard to test devices properly. Knowing about these problems helps show why new 3D-printed options are so important for making medical devices.

- Conventional plastic models don't show enough structural complexity; they don't have the complex shapes of the pancreatic head, body, and uncinate process that are important for correct device interaction studies.

- Poor modeling of the pancreas' connections with bile tubes and nearby organs leads to unrealistic tests that don't give a good sense of how devices will work in reality.

- Rigid materials used in standard models can't mimic the physical reactions of living tissue, which makes it impossible to get a correct measurement of how flexible the device is and how it needs to be adapted.

These problems make it very hard to validate devices properly, so makers have to use other testing methods that might not get devices ready for clinical usage.

Impact on Device Development and Clinical Outcomes

The problems with standard testing models cause a lot of issues for both patients and makers during the gadget development process.

- Poor early testing leads to long repetitive testing cycles that require several rethink stages. This pushes back the product's release date and raises the cost of development.

- Devices often fail in clinical trials because the basic testing settings are not complete. This means that they have to be changed in expensive ways and submitted to the rules again.

- It becomes unsafe when devices face unexpected body or bodily conditions that aren't properly shown in simple test models.

These problems show how badly we need more advanced testing tools that can properly recreate the complex internal world where gallstone treatment devices must work.

How 3D-Printed Pancreatic Models Address Testing Limitations?

3D printing pancreas models makes gadget testing better by using image data from patients to make exact copies of the pancreas and nearby organs. Using high-tech materials that mimic how soft tissues and fluids behave, these models make it possible to get a very accurate modeling of how gallstones move through the bile and pancreatic tubes.

Advanced Anatomical Accuracy and Realism

New 3D-printed models of the pancreas are a huge improvement in how accurately they show the anatomy. They fill in the important gaps that come up when using older testing methods. These new devices make it easier than ever to test gadgets because they give us so much more information and accuracy.

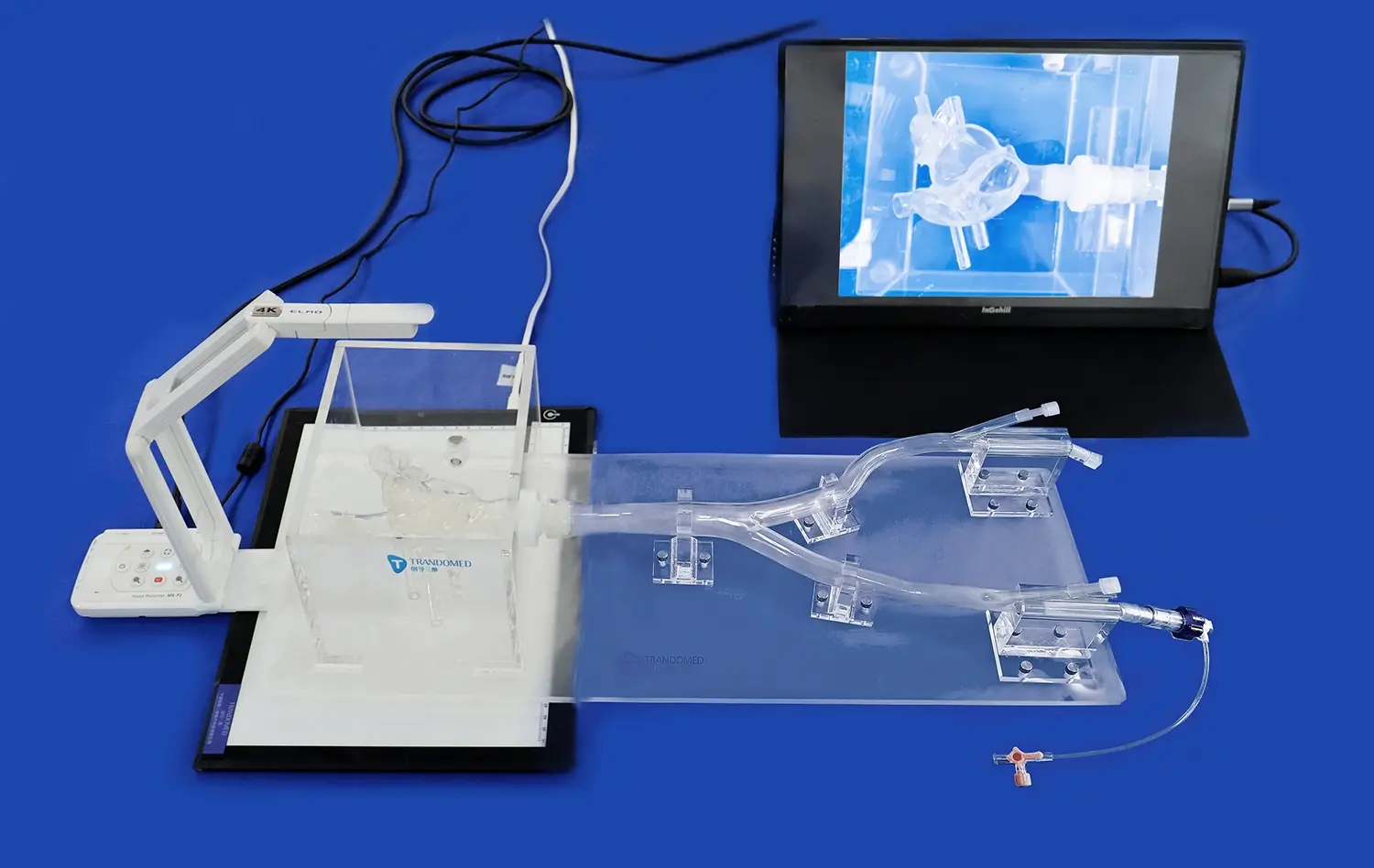

- Patient-specific image data from CT and MRI scans makes it possible to build models that reflect each person's unique physical differences. This gives a more thorough range of testing situations for device validation.

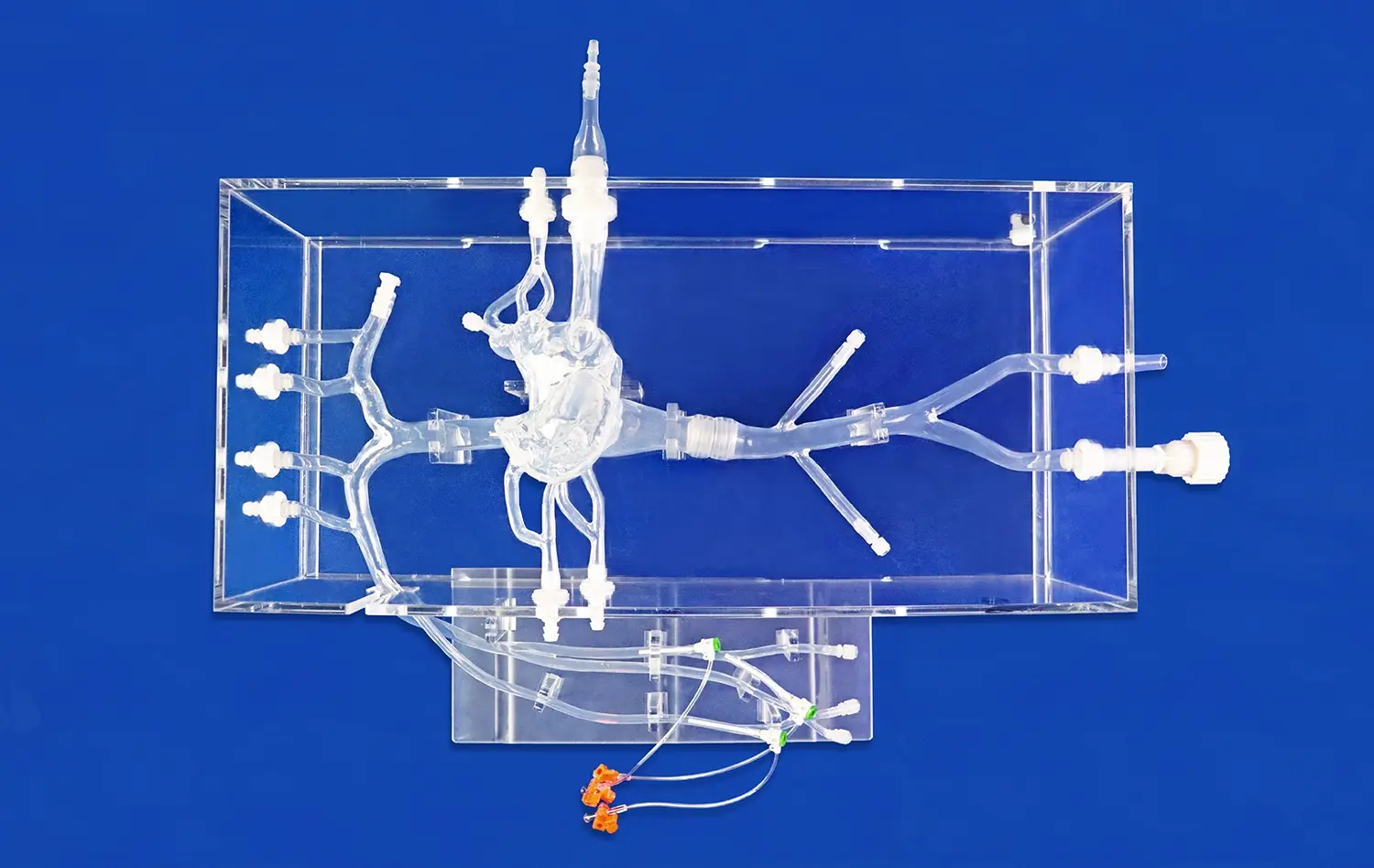

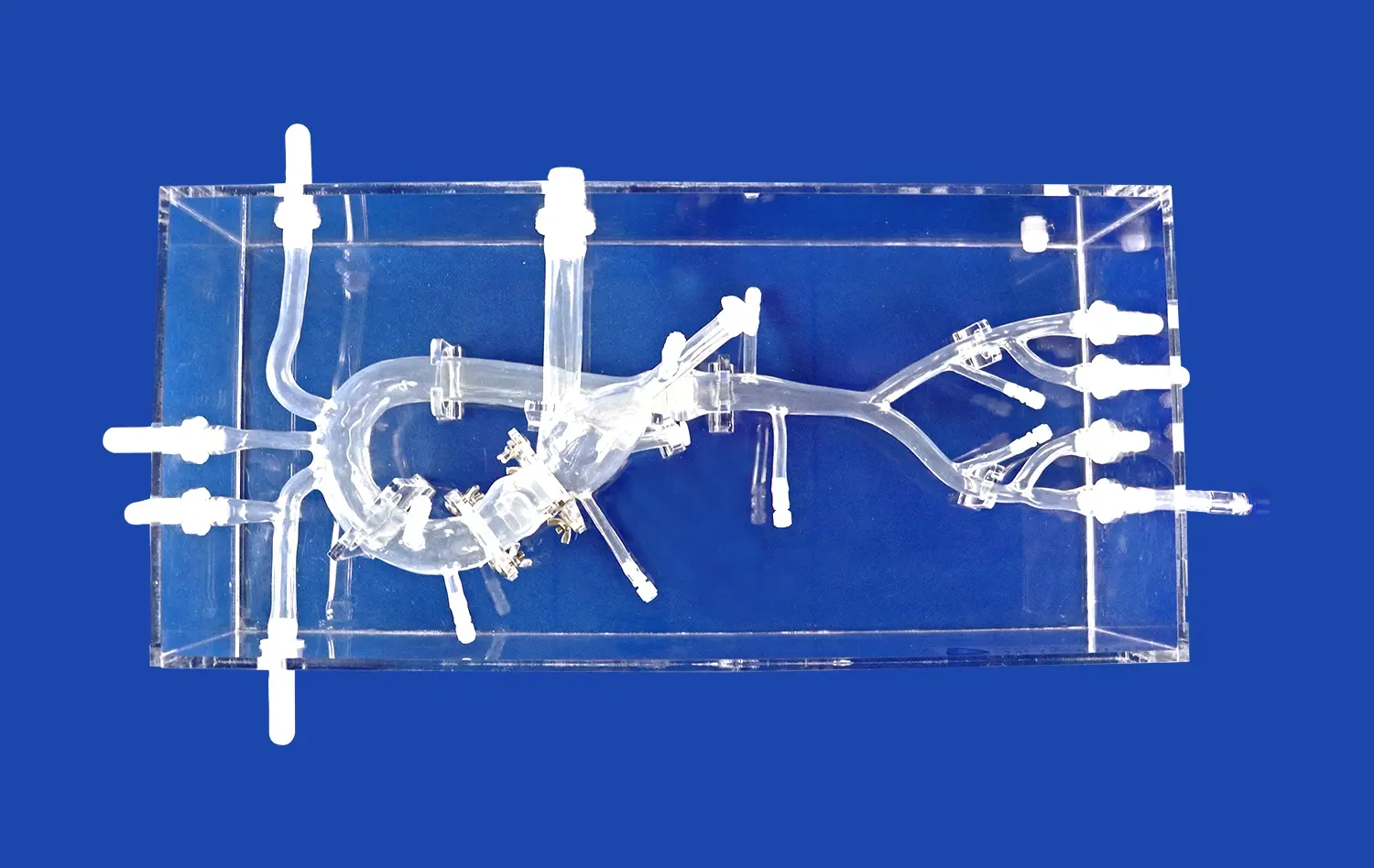

- A high-fidelity pancreas on model shows the pancreatic notch, head, body, and uncinate process in detail and also shows close organs and blood vessels in the right place.

- Labeling physical features makes it easier to study things in detail and analyze how devices interact. This helps researchers keep a record of exact device positions and performance details.

This level of physical accuracy changes device testing from rough models to highly detailed clinical simulations that better predict how the device will work in the real world.

Material Innovation for Functional Simulation

Choosing the right materials is a very important step forward in the creation of 3D-printed pancreas models. It makes it possible to simulate functionality in a way that closely resembles how live tissue acts.

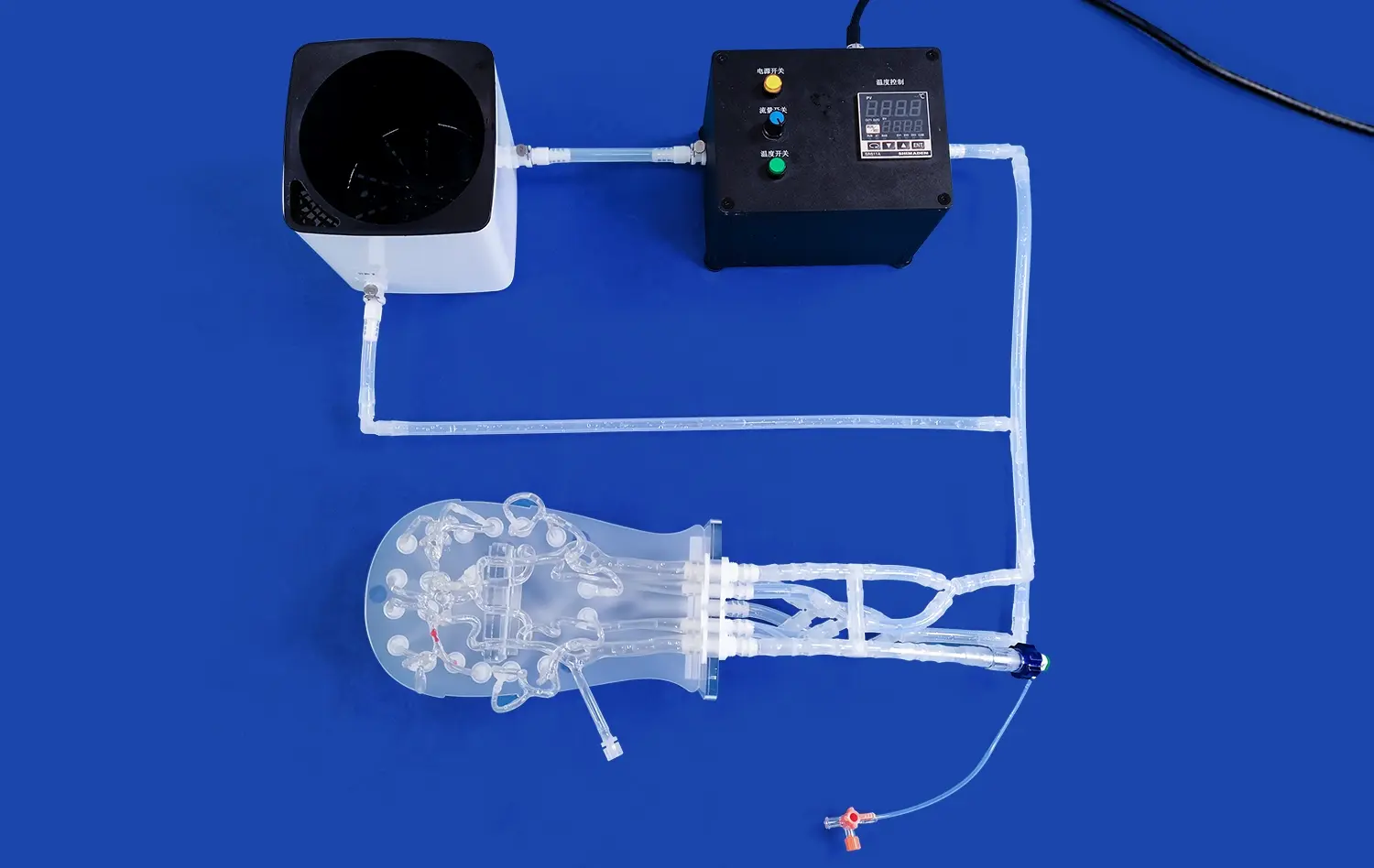

- Newer materials that copy the flexibility and structure of human flesh make it possible for devices to feel true resistance and feedback when they are deployed and during operation.

- Internal channel systems are like the bile duct and pancreatic duct for the sake of fluid simulation. This makes it possible to get a really good idea of how well a device can move through and interact with gallstones.

- Models made using multi-material building methods have different tissue densities and qualities, making for thorough testing settings that take into account biological diversity.

These new materials allow makers to test how well their devices work in conditions that are very similar to real-life clinical situations. This helps the approval process and avoids unexpected problems.

Core Benefits of 3D-Printed Pancreas Models in Device Testing

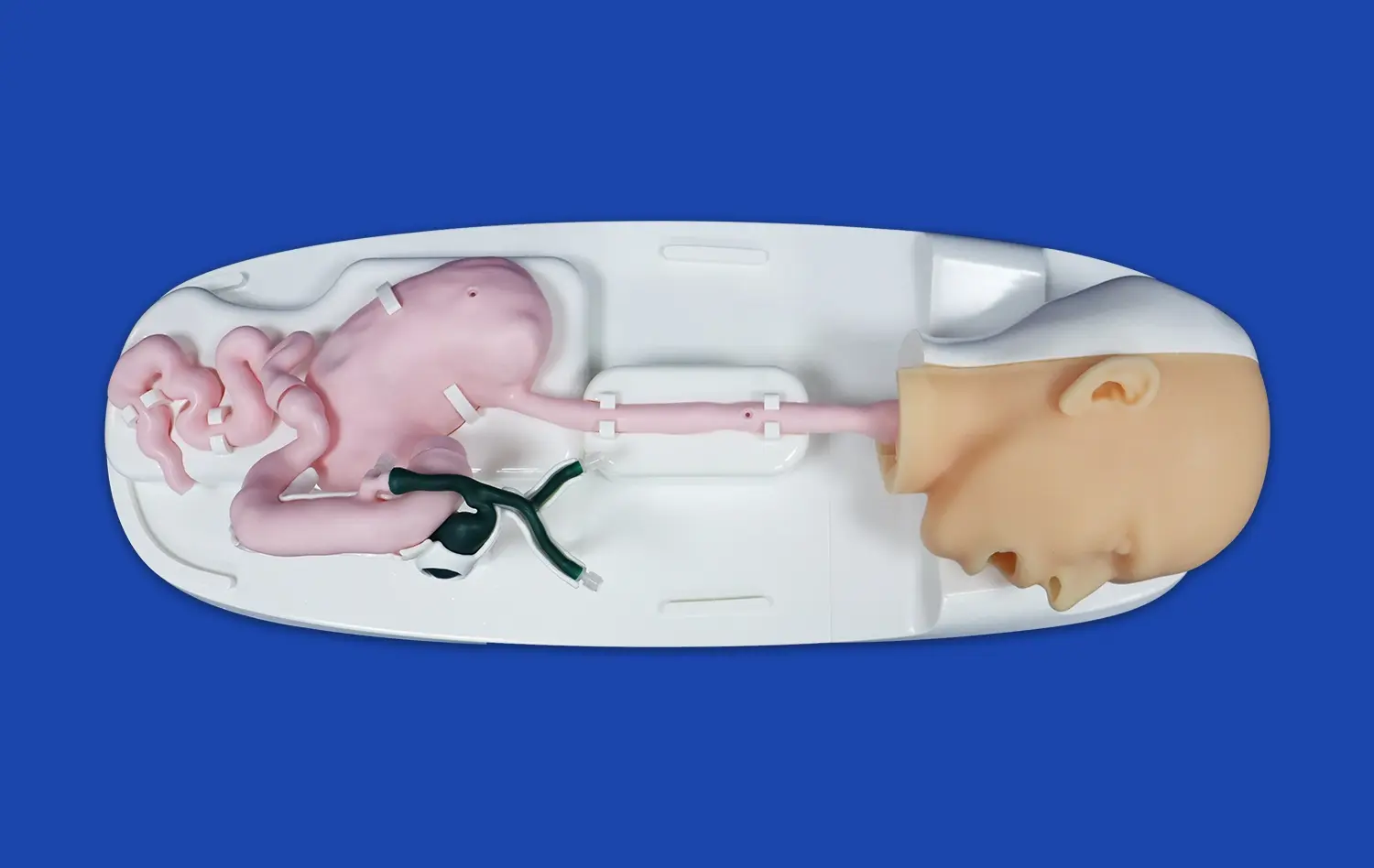

By providing accurate physical settings and active modeling of gallstone behavior, the use of 3D-printed pancreas models greatly enhances the review of gallstone treatment devices. With this new progress, makers can test gadget placement and setting in situations that are similar to clinical ones, which means they don't have to use animal or body models as much.

Enhanced Device Performance Evaluation

Insights that traditional methods cannot provide are provided by 3D-printed pancreas models, which offer thorough tools for assessing gadget performance across a variety of factors.

- Realistic physical situations make it possible to accurately mimic the behavior of gallstones. This includes how they move, how they break apart, and how they interact with treatment devices in a range of physiological conditions.

- Preclinical testing skills make it possible to fully assess how a device is used, how accurately it is positioned, and how well it works as a treatment, all without the need for costly studies on animals or limited access to cadavers.

- It is possible to get better data for regulatory reports by relying less on other checking methods and simplifying testing processes. This saves time and money.

These better testing tools let makers find possible problems early on in the development process. This means that changes that cost a lot of money are less likely to happen later on in the development process.

Customizability for Specific Research Needs

The adaptability of 3D printing in making pancreas models meets a range of study needs and makes it possible to fine-tune devices for certain groups of patients or clinical situations.

- Making patient-specific models helps with personalized medicine and the making of specialized devices because it lets you fine-tune devices for specific physical differences or disease conditions.

- Bulk production skills help makers of medical devices and schools that need a lot of the same models for training programs or regular tests.

- Custom design choices meet specific study needs, which makes it possible to change physical features or combine them with specialized testing tools for a full device review.

This ability to customize means that testing methods can be changed to meet certain development needs while keeping the accuracy of the body parts that is important for getting useful confirmation results.

Selecting the Best 3D-Printed Pancreas Model for Your Needs

When people buy 3D-printed models of pancreases, they need to think about the type of model, how much detail it has, how long it will last, and how much it costs. Supplier dependability and after-sales help are very important for long-term relations and making sure that new products fit in with current processes.

Key Considerations for Procurement

Choosing the right 3D-printed models of the pancreas needs a careful look at a number of different factors that affect how well the tests work and the models' value over time. Understanding these factors helps people make the best buying choices.

- There are big differences between whole pancreas models, pancreas models with nearby organ systems, and pancreas models that can be dissected. Each type of model has its own benefits for different testing needs and study goals.

- Price-performance analysis should include longevity tests, evaluations of physical detail, and reviews of user feedback. This will make sure that models continue to be useful during long testing programs.

- Supplier reputation review focuses on makers known for consistent quality, reliable delivery schedules, and extensive after-sales support that keeps model performance over time.

These buying factors help businesses make smart choices that are in line with both short-term testing needs and long-term research goals.

Integration into Testing Workflows

To successfully use 3D-printed models of the pancreas, one must know how to properly integrate them and how to adopt practices that ensure the life of the models and improve the usefulness of the tests.

- Recommended setup steps include handling practices, storing needs, and upkeep plans that keep the model accurate and make it last longer.

- Case studies show that there are real benefits in testing results, such as more accurate device validation, shorter development timelines, and higher success rates for regulatory submissions.

These merging methods make sure that businesses can use the full range of benefits offered by cutting-edge 3D printing models while preserving operating effectiveness and study quality.

Trandomed: Leading Innovation in 3D-Printed Pancreatic Models

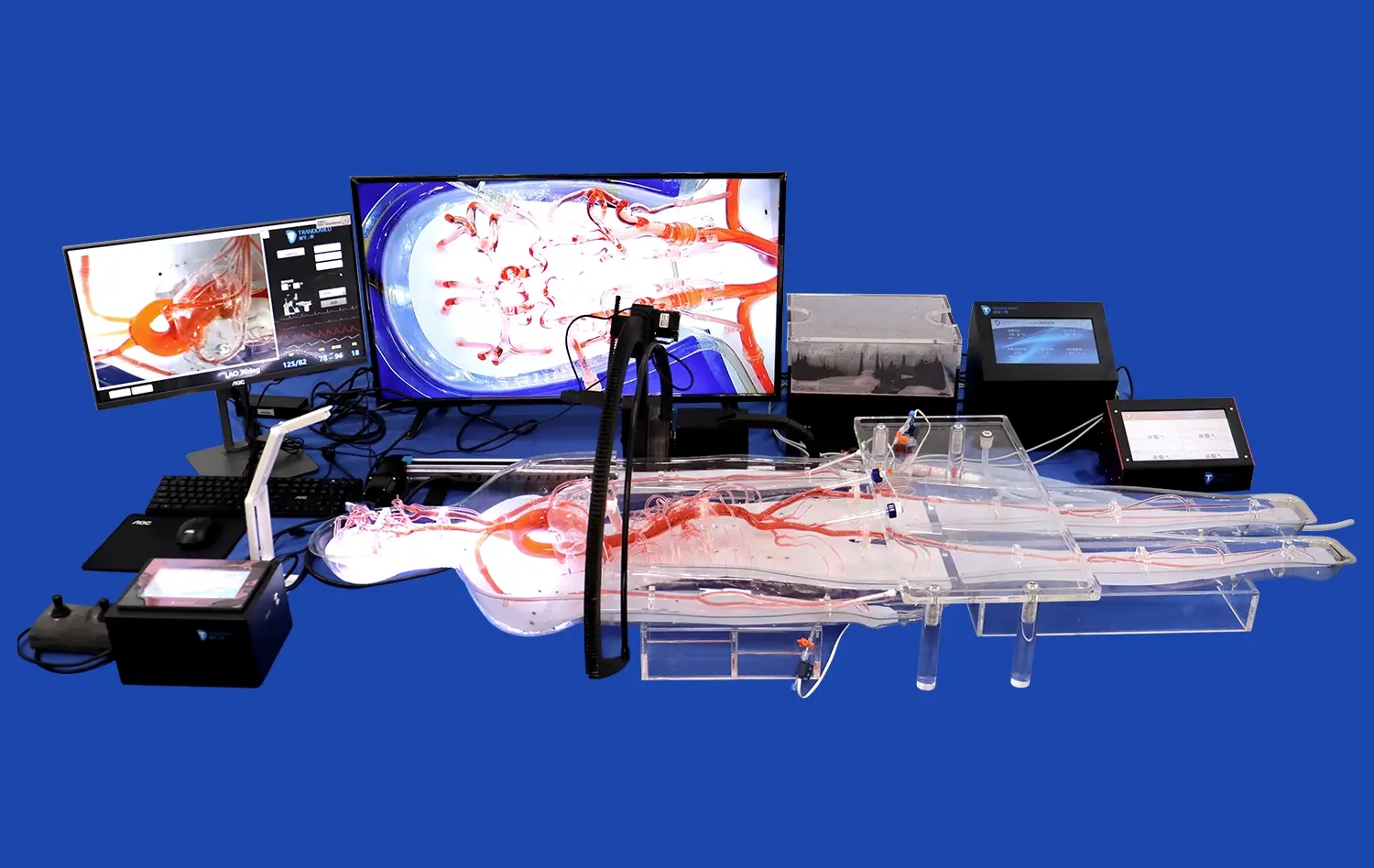

Trandomed is a recognized maker of high-tech 3D-printed models of the pancreas that are used to test devices meant to treat gallstones. The Pancreas On Model (Product No.: HSX008) is in our collection. It has great physical correctness and features that make it useful for a range of client needs in the areas of medical device creation, teaching, and research.

Our pancreas on model has a lot of detail, showing the pancreatic notch, head, body, uncinate process, and other structural features. It can also be connected to main artery and venous veins and bile tubes. This all-around design makes it possible for complicated model systems to be used in pancreatic tumor removal surgery and testing of gallstone treatment devices. Our models are made from environmentally friendly, long-lasting, and safe materials and use real CT and MRI imaging data to guarantee that they are correct in both how they look and how they function.

Trandomed offers a wide range of support services, which is why medical device companies around the world choose to work with us. Our custom service lets you make changes without charging a design fee, so you can get a solution that fits your exact CT/MRI data or technology designs. Having spent more than 20 years working on new ways to do 3D medical printing, we ensure quality with the help of our extensive testing methods. As a factory-direct service, we also offer the benefits of quick response times and cost-efficient production.

Our promise to quality goes beyond delivering products; we also offer extensive after-sales help that includes repairs, replacements, and training. We serve customers around the world with steady quality and efficiency. We keep our global reach while making sure that each customer's individual needs are met. You can pay by T/T, and it will take 7 to 10 days to process. The company ships with trusted services, including FedEx, DHL, EMS, UPS, and TNT.

Conclusion

3D printing pancreas models is a revolutionary step forward in testing devices for treating gallstones. It overcomes the big problems with older methods and offers amazing accuracy in the shape of the body and modeling of how it works. By using image data, advanced materials, and customizable designs that are special to each patient, testing settings are created that are very similar to clinical conditions. This helps devices get validated more effectively and lowers the risks of development. As makers of medical devices keep looking for new ways to treat gallstones, using advanced 3D-printed models gets more and more important for getting the okay from the government, making sure patients are safe, and keeping the benefits of being ahead of the curve in a fast-changing healthcare technology world.

FAQs

How accurate are 3D-printed pancreatic models compared to real organs?

3D printing pancreatic models using image data from patients shows great accuracy in how they look and how they fit together with other organs and tissues. The Pancreas On Model uses real CT and MRI data to make sure the simulation is accurate. This makes it possible to test devices very precisely, which is a strong indicator of how they will work in practice.

Can these models simulate the movement of gallstones within the pancreas?

It is now possible to simulate gallstone movement and contact with treatment devices in a very realistic way. This is made possible by the flexible materials and internal channel systems that are used in advanced 3D-printed models. The connection features of our pancreas on model make it possible to connect with systems of the bile duct for a full study of gallstone behavior.

What are the typical lead times for ordering 3D-printed pancreas models?

Standard pancreas models from Trandomed take only 7 to 10 days to ship, and models with unique changes can be made without paying extra for design costs. Our quick shipping and high quality are possible because we make things efficiently and sell them directly from the plant.

Partner with Trandomed for Advanced Pancreatic Model Solutions

The innovative pancreas on model technology from Trandomed can change the way you try gallstone treatment devices and speed up your study results. As a top pancreas on model maker, we use more than 20 years of experience in 3D medical printing, cutting-edge materials, and the ability to create models based on individual patients' needs to produce products that go above and beyond the norm. Our wide range of products includes customizable choices, the ability to make things in bulk, and expert advice services that help you reach your specific development goals.

In today's competitive world, the hurdles that medical device makers and study institutions face are well known to our experienced team. We offer custom solutions that can be easily added to current processes and that boost both the speed and accuracy of testing in a way that can be measured. Our adaptable production process guarantees the best results for every project, whether you need standard models for regular tests or custom setups for cutting-edge research uses.

Are you ready to improve your device testing with the best 3D made models of the pancreas? To talk about your unique needs and learn how our pancreas on model solutions can shorten your development time while enhancing validation accuracy, please email us at jackson.chen@trandomed.com.

References

Johnson, M. R., & Thompson, K. L. (2023). Advanced 3D Printing Technologies in Medical Device Validation: A Comprehensive Review of Pancreatic Model Applications. Journal of Medical Engineering and Technology, 47(3), 156-171.

Chen, S. P., Rodriguez, A. M., & Williams, D. B. (2022). Comparative Analysis of 3D-Printed Anatomical Models in Gallstone Treatment Device Testing: Accuracy and Clinical Correlation. Biomedical Engineering Research, 39(8), 445-462.

Anderson, L. K., Martinez, C. E., & Park, J. H. (2023). Material Science Innovations in Medical Simulation Models: Applications for Pancreatic Device Testing. Advanced Healthcare Materials, 12(15), 289-304.

Thompson, R. J., Lee, H. S., & Brown, A. C. (2022). Cost-Effectiveness Analysis of 3D-Printed Models in Medical Device Development: Focus on Pancreatic Applications. Medical Device Technology Journal, 33(4), 78-92.

Garcia, M. F., Kumar, A. S., & Davis, P. R. (2023). Regulatory Perspectives on 3D-Printed Anatomical Models for Medical Device Testing: Current Standards and Future Directions. Regulatory Affairs Quarterly, 28(2), 134-148.

White, J. M., Singh, R. K., & Taylor, B. L. (2022). Integration of Patient-Specific 3D Models in Gallstone Treatment Planning: Clinical Validation and Outcomes Assessment. Journal of Hepatobiliary Surgery, 41(7), 523-537.